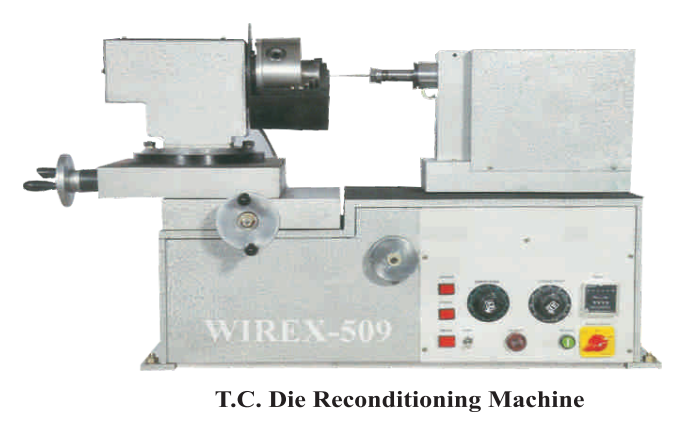

T.C. DIE RECONDITIONING MACHINE

Wirex 509

The machine is designed and developed for working and polishing of Tungsten Carbide dies. Wirex Tungsten carbide die working machine is the ideal solution for grinding and polishing of the entire range of tungsten carbides dies. Our equipment is effectively designed for working bearing portions and reduction angles in one setting.

FEATURES

- Fast Resizing & Polishing of bearing and reduction angle in one setting.

- Variable stroke speed.

- Variable Die rotation.

- Die holding through chuck.

- Needle fixing through collet.

- Buzzer system through timer.

- High productivity & finishing.

- Easy to operate.

TECHNICAL SPECIFICATIONS

- Spindle Speed : 8000rpm

- Die Size : – 0.50 to 20.00 mm

- Die Case Size :- Up to 125mm

- Operation :- Semi Auto

- Die Reduction Angle : 0 to 30 degree per side

- Die Rot Speed : 0 -500rpm Variable

- Stroke Speed : 0 -300 st per min

- Stroke Length : 0 -20mm

- Collet : Dia 3, 6 & 8mm

- Timer : 0-999 min.

- Input Volt : 230 V Phase 50Hz.

- Machine Weight : 130Kg approx

- Machine Dimension : L500 X W50 X H650

NEEDLE GRINDER

FEATURES

- For grinding and re sharpening for new and worm out steel pins.

- Accurate marking are provided for accurate angle.

- Wheel cover provided dust collecting and safety.

- Pin holding through collet.

TECHNICAL SPECIFICATIONS

- Angle Adjustment : 0to 30 Degree

- Collet Dia : 3,6&8mm (different Size On Request)

- Type Of Grinding Wheel : Grade A46 /54k5v10

- Grinding Wheel Speed : 2800 Rpm

- Needle Rotation Speed : 300 Rpm

- Wheel Size : dia 100 X50 X31.75

- Power Supply : 230vac 50 Hz

- Machine Weight : 60 Kg Approx

- Machine Dimension : L500x W350x H400

The Machine Is Designed And Developed For Angle Grinding For Hard Steel Pins. Wirex Grinding Machine Is The Ideal Solution For Grinding For Angle As you required

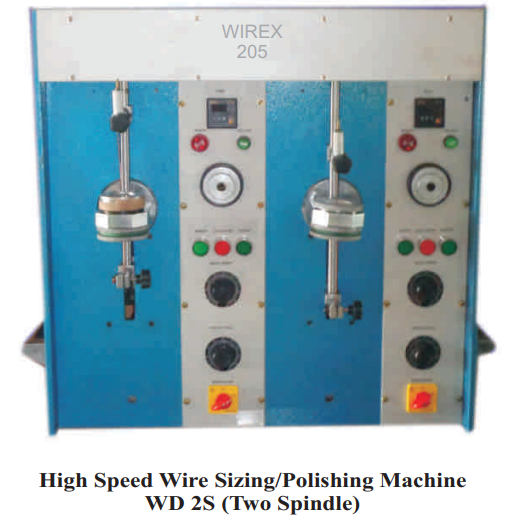

WIRE POLISHING MACHINES

TECHNICAL DETAILS

- Die size : 0.10 to 3.00mm

- Operation : semi auto

- Die rotation speed :0-3000 RPM

- Stroke speed : 0 to 400 st per min

- Stroke length :80mm

- Die case size : 25 ,28

- Die oscillation :0 to 15 degree per side

- Timer :0 to 999 min

- Power supply : 230v Ac 50hz

- Machine weight :

- WD 1S 100 kg approx

- WD 2S 170 kg approx

- WD 3S 300 kg approx

- Machine dimension :

- WD 1S L400 x W380 x H710

- WD 2S L710 x W380 x H710

- WD 3S L102010 x W380 x H710

The machine is designed and developed for sizing & polishing of poly crystalline. natural & mono diamond dies of size ranging from 0.10 – 3mm

The wire type die polishing system from WIREX dies provides superior die

precision and quality to maximize the cost effectiveness of in-house die recutting, economical and easy to use.

The machine is manufactured with precision engineering. This machine

onsists of oscillation die holder. Die holder is of self centering type, die rotation and stroke speeds are continuously variable.

FEATURES

- Fast re sizing and polishing of die

- Stroke speed can variable . Die rotation can variable

- Self centering type die holder spring type collet or (Option V type die holder)

- Oscillation process in blending for exit and angle meting point to

smooth wire drawing - Buzzer system connected trough timer

- Increase high productivity

- Good finishing

- Easy to operate

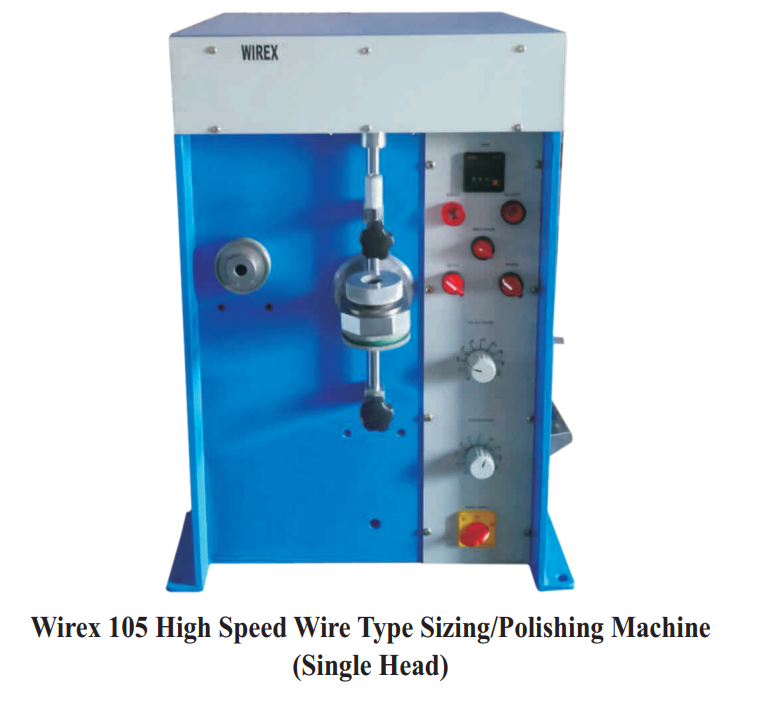

WIREX 105 WIRE TYPE DIE POLISHING SYSTEM

Wirex 105 wire type die polishing system provides superior die precision and quality to maximize the cost effectiveness of in-house die recutting, economical and easy to use.

TECHNICAL SPECIFICATION

- Working Range 0.5- 10mm.

- Single Spindle.

- Die Turntable Speed : 0-3000rpm.

- Stroke Speed : 0-1000/min.

- Stroke Length : 70mm.

- Separate Speed Control for Die

- Rotation and Vertical Stroke.

- Die Casing Capacity : 25,28 And 43mm.

- Timer Setting : 1 Sec. 999 Min.

- Electrical Supply : 220v/50hs (Single Phase).

- Dimensions In mm : L 550 x H 350 x W 570.

- Net Weight : 95kgs. Approx.

WIREX ULTRASONIC DIE RECONDITIONING MACHINE WITH OSCILLATION

Wirex Ultrasonic Machines are designed for recutting and polishing PCD, ND and MONO DIAMOND DIES

Wirex 250 Technical Specifications

- Working Range : 0.100 – 3.50mm

- Ultrasonic Generator 150w/56khz.

- Electrical Supply : AC 100v 50hz

- Frequency : 22, + / – 5khz

- Cooling : Forced Air.

- Die Rotating Speed : 123 Turn/min

- Die Case Size 25mm, 28mm, 43mm

- Working Rotating Angle : 10º – 25º

- Spindle Type : Hydraulic

- Machine Weight : 55kg

Wirex 350Technical Specifications

- Working Range 0.150 – 8.000mm

- Ultrasonic Generator 300w/56khz.

- Electrical Supply : AC 220v 50hz

- Frequency : 22-27.5 khz

- Cooling : Forced Air.

- Die Rotating Speed : 123 Turn/min

- Die Case Size 25mm, 28mm, 43mm

- Working Rotating Angle : 10º – 25º

- Spindle Type : Hydraulic

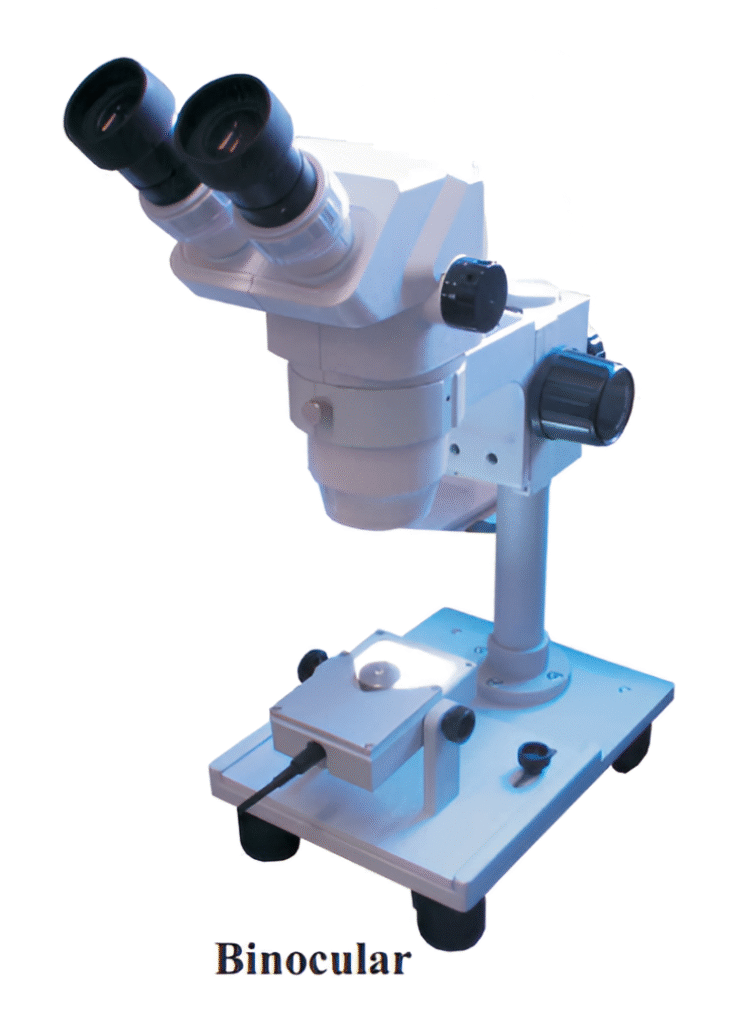

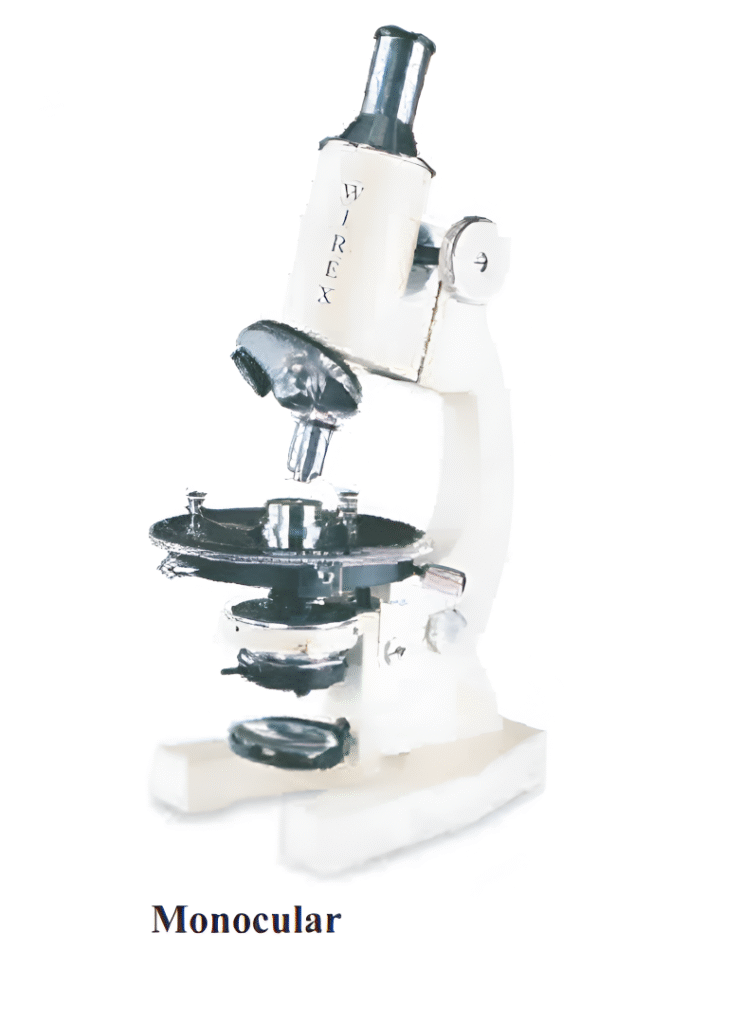

Microscopes

A special sliding support with 120 tilting die table enables die to be viewed from all angles which is crucial during the inspection.

Specially designed for inspecting the fine dies, Sizes from O.010mm & RBD dies upto 12mm Total Magnification Available

Technical Specifications

- Die Holder : 25 and 28 mm 43 mm (optional)

- Optics : Eyepiece IOX (20x Optional)

- Objective : Stereo Zoom 1-4x

- Illuminated : Frosted Bulb 60w

Wirex Ultrasonic Die Cleaner

Ultrasonic cleaners manufactured by WIREX are used for cleaning wire drawing dies and other small parts from Lubricants, enamels and diamond powder/paste etc. Detergent fluid can be plain water or detergent as needed.

It offers a convenient method for cleaning with its safe and consistent operation

MODEL : WIREX 50

POWER SUPPLY: 220V50HZ

MAY OUTPUT POWER: 180W

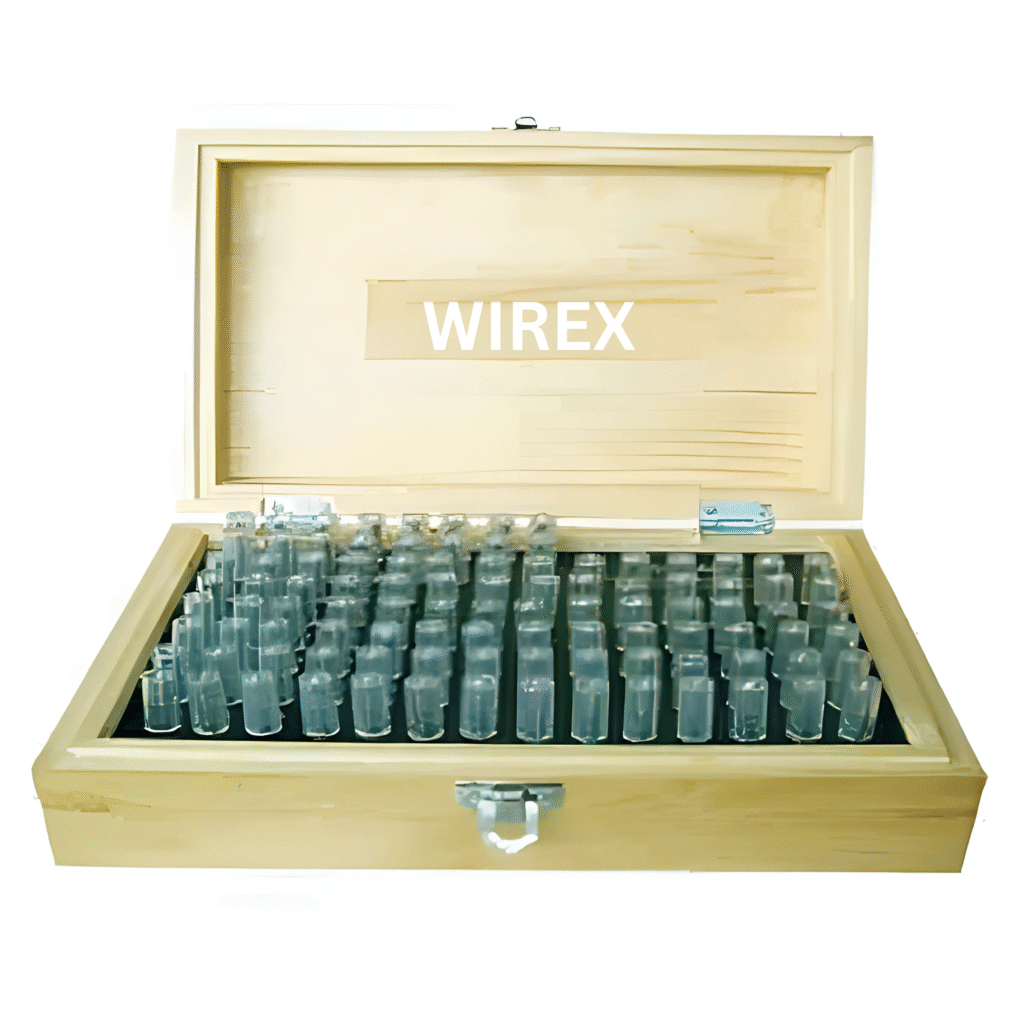

Measuring Pins

MEASURING PINS STANDARD SET

Applications

Measuring Pins for checking of bores, center distances, groove dimensions, inspection of micro-meters, gear measurements etc.

Features

- Manufactured as per IS 11103: 1984 / DIN 2269

- Measuring pins are manufactured from high quality high alloy & are sub zero treated for dimensional stability.

- Calibration Certificate traceable to National/ international standards issued with each set & loose pins.

- Made of High Quality Alloy Steel (EN31)

- Available in steps of 0.01, 0.02 and 0.05 mm.

- Hardness : Heat treated to a hardness of Rockwell 58 to 63 HRC

- Lapped to impart high surface finish.

- Mfg. Tolerance +/- 0.001/0.002 mm on diameter.

- Carefully packed in fancy wooden case for easy handling.

- For extra safety pins will be provided in individual Plastic Containers up to 7 mm.

RANGE IN STEP OF O.02mm

| Set Range in mm | No. of Pins |

| 0.50-1.00 | 26 |

| 1.02-3.00 | 100 |

| 3.02-5.00 | 100 |

| 5.02-7.00 | 100 |

| 7.02-10.00 | 100 |

| 10.02-12.00 | 100 |

| 12.02- 14.00 | 100 |

| 14.02-16.00 | 100 |

| 16.02-17.50 | 75 |

| 17.52-19.00 | 75 |

| 19.02-20.00 | 50 |

RANGE IN STEP OF O.05mm

| Set Range in mm | No. of Pins |

| 0.50-2.00 | 31 |

| 2.05-7.00 | 100 |

| 7.05-12.00 | 100 |

| 12.05-15.00 | 60 |

| 15.05-18.00 | 60 |

| 18.05-20.00 | 40 |

Notes :

Pins Without Knob :

0.5mm to 3.00mm – Length 40mm

3.00mm and above – Length 50mm

Pins with Knob :

5mm length from above standard length is embedded into the knob.

RANGE IN STEP OF O.01mm

| Set Range in mm | No. of Pin |

| 0.20-0.49 | 30 |

| 0.50-0.99 | 50 |

| 1.00-2.00 | 101 |

| 2.01-3.00 | 100 |

| 3.01-4.00 | 100 |

| 4.01-5.00 | 100 |

| 5.01-6.00 | 100 |

| 6.01-10.00 | 100 |

| 7.01-8.00 | 100 |

| 8.01-9.00 | 100 |

| 9.01-10.00 | 100 |

| 10.01-11.00 | 100 |

| 11.01-12.00 | 100 |

| 12.01-13.00 | 100 |

| 13.01-14.00 | 100 |

| 14.01-15.00 | 100 |

| 15.01-16.00 | 100 |

| 16.01-16.75 | 75 |

| 16.76-17.50 | 75 |

| 17.51-18.25 | 75 |

| 18.26-19.00 | 75 |

| 19.01-19.50 | 50 |

| 19.51-20.00 | 50 |